Advanced Cryogenic Solutions

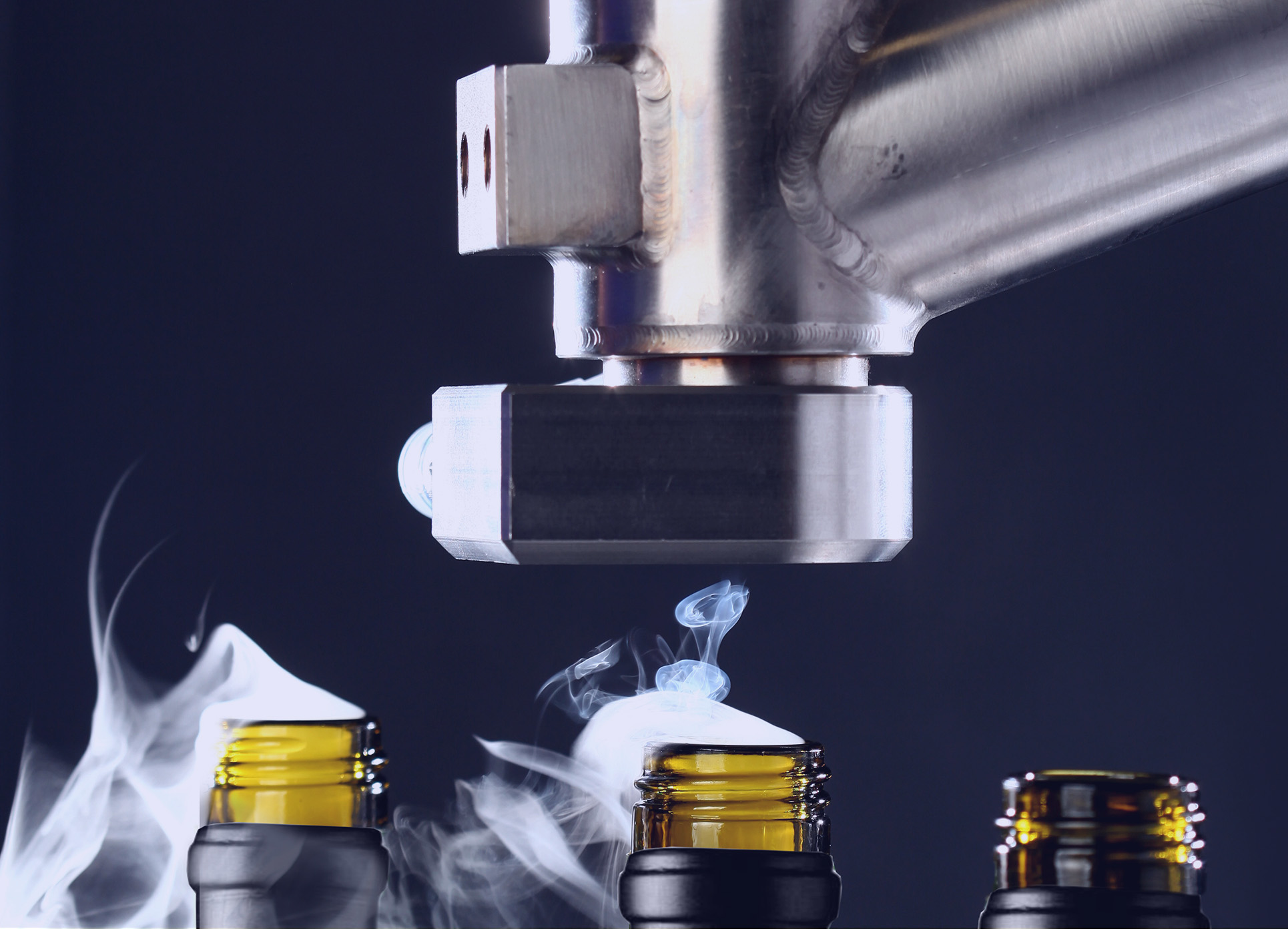

Precision liquid nitrogen dosing systems that reduce packaging costs, improve product quality, and enhance operational efficiency across beverage, food, and pharmaceutical industries.

Reducing Waste & Cost One Drop at a Time

One part of liquid nitrogen (LN₂) warms and expands into 700 parts of gaseous nitrogen at ambient temperature. Our automated dosers dispense a precisely measured dose of LN₂ into each container prior to sealing. The trapped LN₂ vaporizes, creating pressure, and adding rigidity to the container – allowing for a thinner container wall.

Liquid nitrogen expands 700 times when it vaporizes at ambient temperature

Automated systems ensure exact measurement for consistent results

Internal pressure allows for lighter packaging and reduced material costs

Typical material cost reduction through optimized packaging

Complete Cryogenic Solutions

From compact craft systems to industrial-scale operations, we have the perfect solution for your needs

UltraDoser SC350

Professional-grade cryogenic dosing system with advanced analog controls and LCD display

Key Features:

Applications:

- • Large breweries

- • Industrial beverage production

- • High-volume canning lines

CryoDoser Flex

Versatile cryogenic system designed for craft breweries and mid-scale operations

Key Features:

Applications:

- • Craft breweries

- • Regional beverage companies

- • Specialty packaging

Inerter System

Advanced touchscreen-controlled system for precision dosing applications

Key Features:

Applications:

- • Premium beverages

- • Pharmaceutical packaging

- • Quality-critical applications

See CryoTools in Action

Our cryogenic systems are powering innovation across multiple industries

Wine & Spirit Production

Precise liquid nitrogen dosing preserves wine quality and extends shelf life by creating an inert atmosphere in bottles, preventing oxidation and maintaining flavor profiles.

Beer & Beverage Canning

Our cryogenic dosing technology creates the perfect internal pressure in canned beverages, ensuring product integrity, optimal carbonation levels, and reduced packaging costs.

Why Choose CryoTools?

Proven benefits that deliver measurable results for your operation

Cost Reduction

Reduce packaging material costs by up to 30% through optimized container design

Quality Improvement

Enhanced product quality through inert atmosphere protection and pressure optimization

Operational Efficiency

Automated dosing systems reduce labor costs and improve production consistency

Environmental Benefits

Reduced material usage and waste contribute to sustainability goals

Scalable Solutions

Systems that grow with your business from craft to industrial scale

Expert Support

Comprehensive training, installation, and ongoing technical support